Installation and Control of Submersible Structures Described

Page Contents

Archimedes’ Principle and Submersible Structures

The DuckHut Duck Blind

Submersible structures Installation involves consideration of several principles of Physics. We are all aware that some objects will float on water. We are also aware of our own “lightness” when immersed in water. It is also observable that other objects are lighter when submerged in water. These are all examples of Archimedes’ principle. Archimedes’ principle states that any floating or submersible structure or body is buoyed up by a force equal to the weight of the fluid it displaces. This principle is valid for a body of any shape and has a very direct bearing on the installation of bodies such as water-tight duck blinds where they are exposed to a body of water or ground water. The process is demonstrated below using a round duck blind as an example installation. The illustrated duck blind was actually built by my son and sold to a hunting club in Kansas. It was installed in a partially flooded field owned by the club.

It can be shown mathematically that the only force exerted by the liquid on the body is in the vertical direction. The magnitude of this force is called the buoyant force. Further, the only forces acting are gravity and buoyancy both of which have vertical lines of action.

Anchoring of Blinds or Other Submersible Structures

Anchoring of the blind in a manner that will counteract this buoyancy force is essential in the presence of water in order to prevent ejection of the blind from the installed position. The total counteracting weight needed depends on the total water exposure and other things such as soil type (some soils are very expansive when they get wet and exert considerable force on embedded objects). The amount of anchoring, or counteracting force, required will vary from little or no anchoring to substantial anchoring to prevent the blind from floating out of the installation site. Determination of these requirements, and proper application of an anchoring system, are the responsibility of the installer and customer. The information provided on this page is provided as guidance only. It is not a prescription for installation. It is provided to alert the customer/installer to some of the considerations involved in installation/use of the pit blind. Considerations include:

- total water exposure.

- depth of installation.

- soil type (backfill with expansive soils will exert strong lateral and vertical forces against the blind as it does home and other foundation types).

- type of water (fresh or salty).

- type materials (such as soil and minerals) in solution with the water.

- temperatures (includes winter freezing).

- exposures to moving water or soil.

20-foot DuckHut Duck Blind External Construction

Anchoring points are shown on each end of the DuckHut blind. However, anchoring requirements are determined by the characteristics of the installation location and method of installation, and the end-point anchors, in most extremely wet locations, will probably be inadequate by themselves. Used alone, they may also cause the blind to buckle upward in the center due to unrestrained buoyant forces. In an installation subject to the hydrostatic pressures of water bodies or ground water, such as in wet/marshy areas, careful attention should be given to distributing anchoring points along the length of the blind in order to resist hydrostatic bending of the blind due to unequal distribution of restraint points. Calculation of the force assumes that the total force acts through the body center of gravity. However, in reality, the force is distributed along the total lifting surface of the body.

The effect of these primary and secondary water induced forces may be reduced by installing the blind over a drainage system similar to those used to protect home foundations and basements. These drainage systems can provide an alternate path to the surface for the water. Installation over a bed of gravel with a back fill of gravel may also provide a “least-resistance” path to the surface and also reduce the effects of expansive soils. This lower resistance path may be further improved by installation of perforated drainpipes along the base of the blind, with venting to daylight. Expansive soil effects may also be reduced by soil replacement with more favorable soils or by substitution of other materials.

Submersible Structures Displacement and Force

For illustration of the procedure, the 20-foot, 48-inch blind will be used. The displacement medium is assumed to be fresh water, and the pit blind body is 100% immersed in the water. Fresh water has a density of 1 kg/liter. The density of salt water is higher. If the total force (restraints, overflowing water, and pit blind weight) counteracting the buoyancy force exceeds the buoyancy force, the blind will take on water and sink, as would a boat.

V = L (pi) r2

Where: L is the length of the pipe (blind) = 20 ft. = 240 inches,

pi = 3.14159,

r is the radius of the pipe = 24 inches.

So, the volume of the pipe is:

V = 240 inches (3.14159) 576 inches2

V = 434,293.4 inches3

Now, 1 cubic inch = 0.01639 liters,

Therefore,

V = (434,293.4 inches cubed) (0.01639 liters/inch cubed)

V = 7,118.1 liters.

1 US gallon = 3.785 liters.

Now, V = (7,118.1 liters) (1gallon/3.785 liters) = 1,880.6 gallons.

One gallon of water weighs 8.34 pounds.

Therefore,

Displacement weight = (8.34 pounds/gallon) (1,880.6 gallons)

= 15,684 pounds.

In order to get the force to be counteracted by the anchoring system, the above 15,684 pounds should be reduced by the weight of the pit blind (the pipe, end plates, seats, shelves, doors, door supports, floor platform, mats, welds, built-in anchors, and any other attachments), water over built-in anchors, water over added anchors (dependent on shape and surface area), and the overflowing water. The above calculated displacement weight overstates the actual anchoring weight needed. It provides a large safety factor.

We should also look at the contributions of the anchor plates welded to each end of the DuckHut blind. The model being discussed has anchor dimensions of 2 ft. X 4 ft. X 1 inch. This gives a displacement volume of 24″ X 48″ X 1″ = 1152 cubic inches. Now, 1 cubic ft. = 12″ X 12″ X 12″ = 1728 cubic inches, and displacement volume is 1152 cubic in./1728 cubic in. = .6667 cubic foot. This displacement volume will displace approximately .667 cubic ft./.1337 = 4.9863 gallons of water. The buoyancy force exerted by this displaced water is 4.9863 gallons/.1198 = 41.6218 pounds. However, if we assume that when the blind is 100% submerged, the anchor is under 4 feet of water, the volume of water acting downward (anchoring force) is found with the previous stated dimensions:

Anchoring water volume = 2′ X 4′ X4′ = 32 cubic feet.

The quantity of water = 32 cubic ft./.1337 = 239.34 gallons.

The weight (or force) of this water is 239.34 gallons/.1198 = 1997.84 pounds, approximately.

Total anchoring weight of anchors = 2 X 1997.84 = 3995.68 pounds in 100% water installation.

We previously calculated the total displacement weight to be 15,684 pounds (less the weight of the blind, other attachments, and overflowing water. To calculate the approximate additional anchoring weight needed (in this 100% water installation) we will continue to ignore the blind weight. All weights should be determined, and trade-offs made in an actual installation which most likely will not have the 100% water characteristics covered here. These calculations illustrate a process only. Using these assumptions, the remaining buoyancy force to be countered by an anchoring system is: 15,684 pounds – 3996 pounds = 11,688 pounds. If a usual density for concrete of 150 pounds/cubic foot is used, we can counter this buoyancy force of 11,688 pounds as follows:

11,688 pounds/150 pounds per cubic ft. = 77.92 cubic ft. of concrete.

77.92 cubic ft./2 = 38.96 cubic ft. of anchorage distributed down each side of blind and running the full length of the blind with appropriate tie points along each anchor.

Now, 20 ft. (X2) = 38.96 cubic ft.

X2 = 38.96 cubic ft./20 ft.

X = sq. root 1.948 sq. ft.

X = approx. 1.4 ft.

Now, an anchor, as calculated above, of 20′ X1.4 ft. X1.4 ft. =39.2 cubic ft.

39.2 cubic ft. X 150 pounds/cubic ft. = 5,880 pounds.

2 X 5,880 pounds = 11,760 pounds and should fully anchor the blind (weight of the blind will reduce this requirement further).

Values of weights of other blind lengths, with a 48-inch diameter, are proportional to the length in relation to the 20-foot length used in the above calculation.

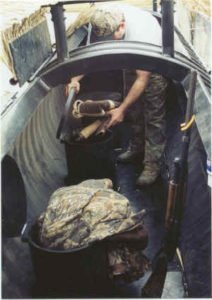

DuckHut Duck Blind in Use

Useful Installation Information Links:

Buoyancy & Archimedes Principle

Comments

Installation and Control of Submersible Structures Described — No Comments

HTML tags allowed in your comment: <a href="" title=""> <abbr title=""> <acronym title=""> <b> <blockquote cite=""> <cite> <code> <del datetime=""> <em> <i> <q cite=""> <s> <strike> <strong>